Data Driven Decisions: Is Your Operation Wise?

6/9/23

The concept of using data for a business advantage is not new. Tom Davenport wrote “Competing on Analytics” in 2006 for the Harvard Business Review, which became a bestselling book the following year. Since then, organizations have continued to invest heavily in data and analytics. But what is analytics? According to the Institute for Operations Research and Management Sciences (INFORMS), analytics is “The Scientific Process of Transforming Data into Insight for Making Better Decisions”.

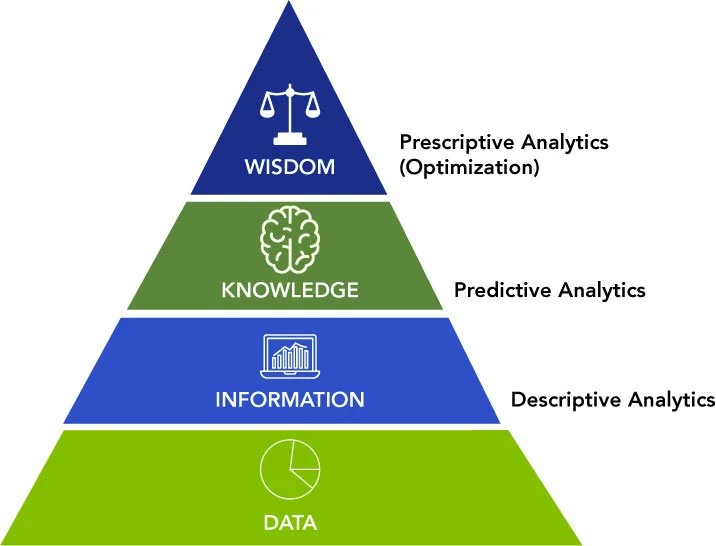

Organizations often say they want to turn data into information and knowledge. Let’s look at how this process generally goes. The first step is to get data in order. Data professionals will extract, cleanse, and load data into new repositories for querying. This step allows data from disparate systems to be viewed and analyzed together. Data Warehouses, Data Marts, Data Lakes, Digital Twins, etc., are built.

With data in order, organizations generally start by wanting to know the current and past state of their business and operations. Countless tools with slick interfaces are available to dissect, slice and dice, and analyze the data. Dashboards and metrics get created, and some organizations build control towers, a suite of tools, to monitor the operations. In this step, the analytics is generally descriptive, with data being turned into information. While descriptive analytics is certainly necessary and valuable, the problem is twofold. First, unless tomorrow is like yesterday, it’s hard to use this information to make lasting changes. Second, often by the time an alert is generated, it’s too late to fix the situation efficiently.

It’s nice to know what’s happening, but we need to know what will happen to truly improve. “Where’s my stuff” is not enough. We need to know “Where and when will my stuff be.” We need to turn information into knowledge and use predictive analytics. Predictive analytics tells us what to expect if we continue the path we are on. We all experience this when we use a navigation system, and it tells us how traffic is impacting our arrival time. The same knowledge can be used for the supply chain. If there’s a delay at a port, we should be able to predict the impact on a warehouse and the final customer.

The uses of predictive analytics are endless. From forecasting demands and inventory, they are predicting supply chain disruption and determining marketing targets. As mentioned, predictive analytics is more valuable than descriptive analytics because we are now looking forward. But even though predictive analytics is very powerful, it’s also not enough. Operators will say it’s important to see that disruption is imminent, but what do we do about it? There are just too many alternative actions, and which one(s) will best meet my needs without creating a new problem?

This is where optimizations come in, or what is known as prescriptive analytics. Wisdom lives here. It may seem like a fine line between knowledge and wisdom, but it can be explained like this: “Knowledge is knowing that a tomato is a fruit…. Wisdom is knowing it doesn’t belong in a fruit salad.”

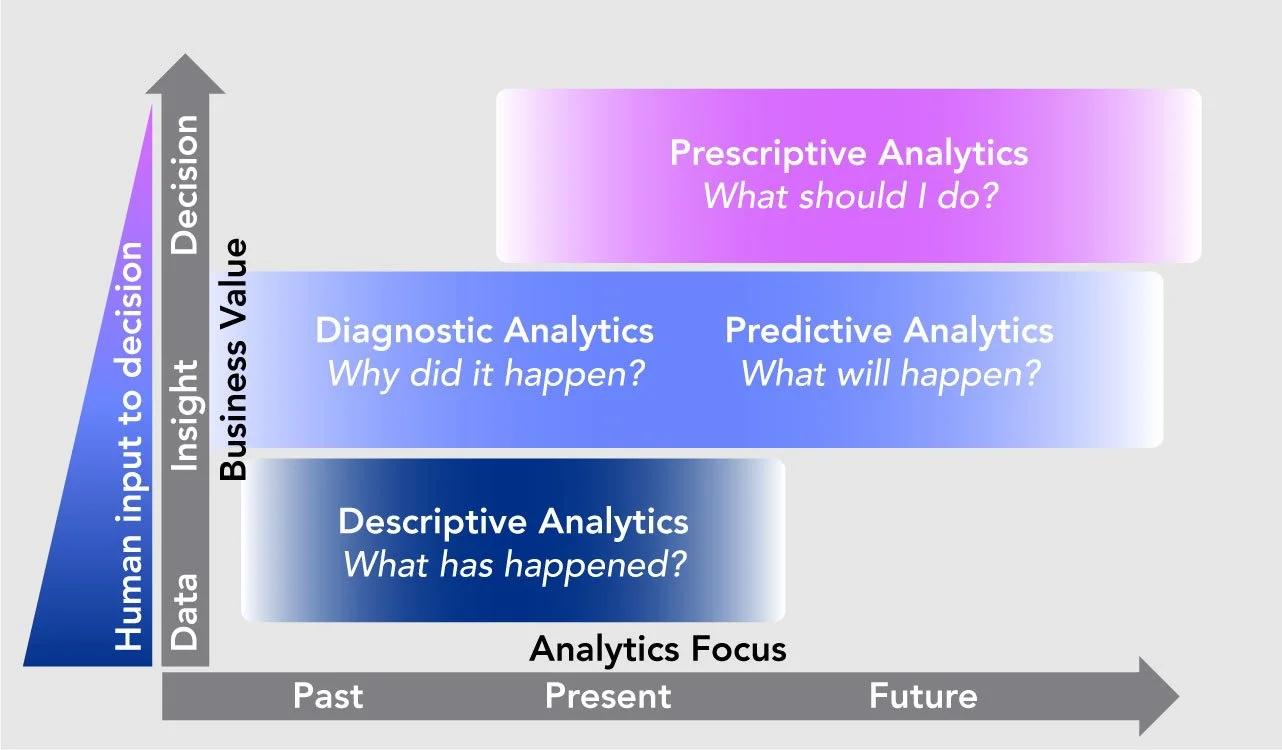

In a wise organization, a new employee, a new planner, or a new operator is making decisions with the wisdom of a seasoned staff member. This is because optimization can look through the countless options of that decision and provide answers or suggestions that meet the business objective while satisfying all the business constraints. This chart below from IBM does a great job of summarizing the types of analytics.

As we look at this chart, we can see some important differences between the types of analytics. Descriptive analytics is looking at the past and present, and the human must make decisions with their domain or company knowledge. Predictive analytics starts looking at the future based on historical trends. The user must still provide significant input into the final decision. With prescriptive analytics, the human input into the decision is reduced as the analytics tool produces answer(s). Think of this as moving from a paper map to GPS Navigation. With the paper map, the user had to decide the best way to get to a destination using their own knowledge and judgment. With GPS Navigation, an address is put in, and the tool determines directions.

As an organization moves through the continuum of analytics from descriptive to predictive to prescriptive optimization, its data needs will grow, the skillset needed by its analytics team will grow, but most importantly, the business impact will grow. The wise organization using prescriptive optimizations is agile, can turn on a dime, and doesn’t accept false choices. They don’t ask whether the goal is to lower costs or provide better customer service. That answer is “Yes!”. A truly wise organization values its data as a company asset and invests in the people and tools to turn the promise into a reality.

As Tom Davenport said, “—applications amassed and applied data in ways that upended customer expectations and optimized operations to unprecedented degrees. They transformed technology from a supporting tool into a strategic weapon.” For those that are early on in this journey, it may seem like a daunting task. It takes leadership, courage, and change management. But there are many examples of organizations demonstrating wisdom.

INFORMS recognizes these wise organizations each year. The recipients of their Edelman Award and INFORMS prize come from a wide array of organizations, including Healthcare, Financial, Regulatory, Agriculture, Manufacturing, and Supply Chain. INFORMS estimates these innovative organizations have saved $363B from 1971 to 2022 while not compromising on customer service.

What this all means is business leaders cannot have their vision end at describing or even predicting. Vision must look to prescriptive optimization. The idea should not be only to turn data into information and knowledge.

Wisdom is the goal.

AUTHOR

Jack Levis, Product Strategy Officer

Jack Levis brings 43 years of logistics and technology experience and has been responsible for developing operational technology solutions at UPS and other businesses, which required advanced analytics to reengineer processes, streamline operations, and maximize productivity.

About ESP

ESP was created by combining over 20 years of supply chain and logistics expertise with technologists that have focused on the science of location and location analytics, the practice of layering geographic data along with business data to extract valuable insights. The advantage that our customers have with ESP is the ability to access and capitalize on a continuously growing infrastructure that enables more focused location-based analytics, helping the supply chain become smarter. ESP has designed a Space and Time Network which enables data (real-time, historic and near real-time) to be consumed, analyzed, viewed, and translated into action. Critical to our customers’ success, our network enables the analyzation of data sets that are beyond typical supply chain data, resulting in more accurate and actionable information.